Our Service Portfolio

From Developement to Assembly - Everything under one Roof

Development and Construction

Over the years, we have acquired a high level of product development expertise.

But our wealth of experience is not limited to product and process development; it involves quality preplanning as well, including advanced product quality planning (APQP), failure mode and effects analysis, and a comprehensive production part approval process (PPAP) carried out with the customer.

Over the years, we have acquired a high level of product development expertise.

But our wealth of experience is not limited to product and process development; it involves quality preplanning as well, including advanced product quality planning (APQP), failure mode and effects analysis, and a comprehensive production part approval process (PPAP) carried out with the customer.

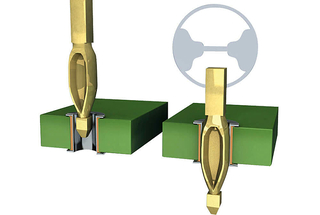

Connection Technology

In addition to tried and proven press-fit technology featuring our patented Tcom press® press-fit zone, ept offers many other types of termination technology products. Soldered connections, THTR, SMT – we offer a suitable solution for every application.

In addition to tried and proven press-fit technology featuring our patented Tcom press® press-fit zone, ept offers many other types of termination technology products. Soldered connections, THTR, SMT – we offer a suitable solution for every application.

In-House Equipment Manufacture

We manufacture all of the necessary tools in our own tool shop. This includes tools for stamping and injection molding, stamping machines, fixture construction, and automation.

We manufacture all of the necessary tools in our own tool shop. This includes tools for stamping and injection molding, stamping machines, fixture construction, and automation.

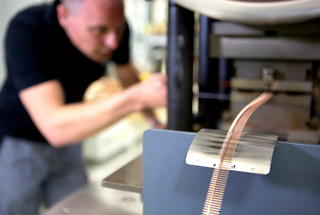

Stamping

Stamped contacts are made in our stamping workshop using machines that we develop and produce ourselves. In the first place, this guarantees maximum profitability and flexibility. But it also enables us to monitor the quality of all aspects of the stamping process.

Our goal is to achieve the perfect balance between tool and machine.

Stamped contacts are made in our stamping workshop using machines that we develop and produce ourselves. In the first place, this guarantees maximum profitability and flexibility. But it also enables us to monitor the quality of all aspects of the stamping process.

Our goal is to achieve the perfect balance between tool and machine.

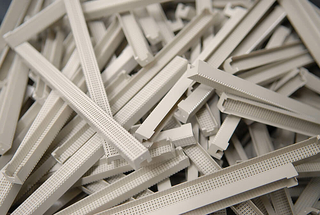

Injection Molding

Insulation and plastic parts are produced using a variety of injection molding machines with different levels of automation, depending on what requirements the product imposes on the processes. Injection molding technology is another one of our core competencies.

Insulation and plastic parts are produced using a variety of injection molding machines with different levels of automation, depending on what requirements the product imposes on the processes. Injection molding technology is another one of our core competencies.

Strip Electroplating

We operate a total of four strip electroplaters with a total of five tracks at two of our plants. Different strip speeds and galvanic bath combinations enable us to produce a large number of surface coatings with a wide range of thicknesses and compositions, for example, Sn, Ni, SnPb, Au, PdNi, and NiP.

We operate a total of four strip electroplaters with a total of five tracks at two of our plants. Different strip speeds and galvanic bath combinations enable us to produce a large number of surface coatings with a wide range of thicknesses and compositions, for example, Sn, Ni, SnPb, Au, PdNi, and NiP.

Manual Assembly and Partially or Fully Automated Assembly

Connectors are assembled using machines and equipment we develop and build ourselves. And of course, we also have in-line inspection systems.

Connectors are assembled using machines and equipment we develop and build ourselves. And of course, we also have in-line inspection systems.