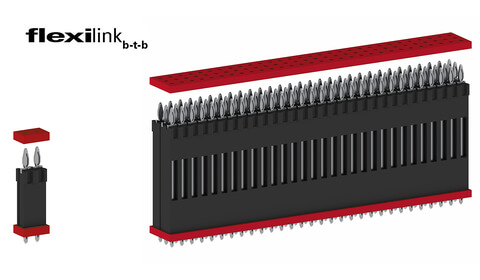

flexilink Board-to-Board Connections

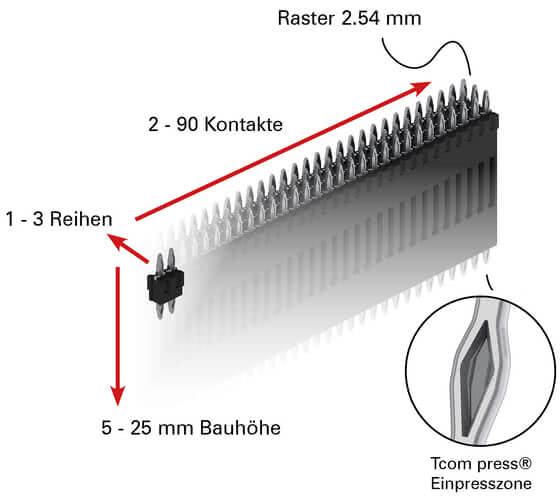

board-to-board

flexilink b-t-b, 5 mm height Part No. 990-52XNN050-110

flexilink b-t-b, 10 mm height Part No. 990-52XNN100-110

flexilink b-t-b, 15 mm height Part No. 990-52XNN150-110

flexilink b-t-b, 20 mm height Part No. 990-52XNN200-110

flexilink b-t-b, 25 mm height Part No. 990-52XNN250-110

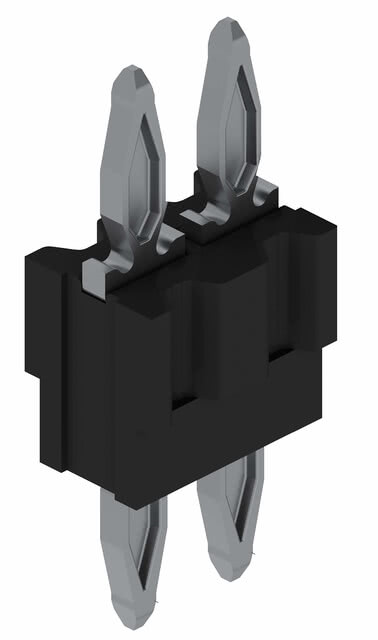

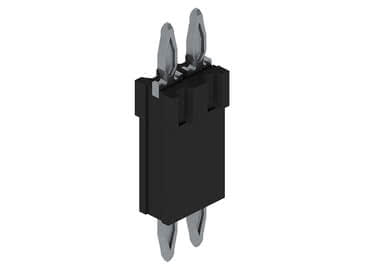

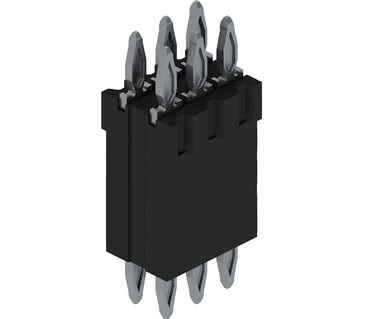

jumper

flexilink jumper, 2 contacts Part No. 991-500200-11

flexilink jumper, 3 contacts Part No. 991-500300-11

flexilink jumper, 4 contacts Part No. 991-500400-11

flexilink jumper, 5 contacts Part No. 991-500500-11

flexilink jumper, 6 contacts Part No. 991-500600-11

flexilink jumper, 7 contacts Part No. 991-500700-11

flexilink jumper, 8 contacts Part No. 991-500800-11

flexilink jumper, 9 contacts Part No. 991-500900-11

flexilink jumper, 10 contacts Part No. 991-501000-11

flexilink jumper, 11 contacts Part No. 991-501100-11

flexilink jumper, 12 contacts Part No. 991-501200-11

flexilink jumper, 13 contacts Part No. 991-501300-11

flexilink jumper, 14 contacts Part No. 991-501400-11

flexilink jumper, 15 contacts Part No. 991-501500-11

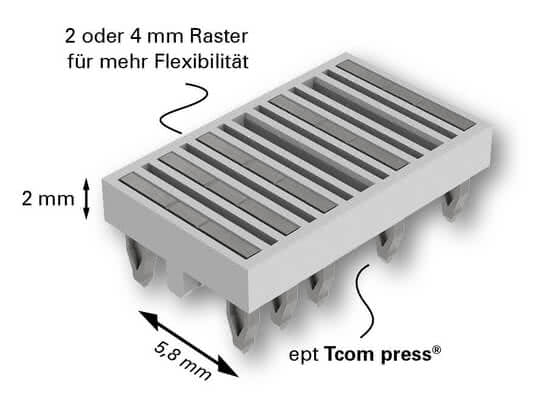

flexilink: Overview

PCB Connector with press-fit technology

The flexilink comes in two variants:

- flexilinkjumper for horizontal PCB connections

- flexilinkb-t-b for parallel PCB connections

It impresses with its space-saving design while at the same time boasting a high current rating. A board-to-board distance of 1 mm and a footprint of only 3.8 mm on the circuit board enable maximum use of space and a range of applications. For example, the connector can be used to daisy-chain LED boards. The circuit board connector is a mere 2 mm high.

This connector and its 2.54 mm grid guarantees you a high-quality PCB connection with its press-fit technology. The two-sided connector is a perfect solution for high switching currents because no contact junction limits current carrying capacity. The advantage of this is evident: A reliable mechanical as well as electrical board-to-board connection is created using just a single part. There is no need for any spacers – not only saving on PCB real estate but also reducing costs. The flexilinkb-t-b adapts to your needs: You can choose flexilinkb-t-b for board-to-board distances of 5 to 25 millimeters as well as combine different rows and numbers of pins.

flexilink jumper Features

applications such as LED strips in building, automation, and automotive electronics. It withstands exceptionally strong mechanical loads such as shock and vibration. No elaborate soldering process is necessary – the flexilinkjumper uses press-fit technology to ensure the easy connection of two or more printed circuit boards.

Features

- Variable pitch from 2–4 millimeters

- 2–15 contact bridges

- Up to 11 Ampere current rating per pin

- Saves space and reduces costs; replaces spacers

- Connection created using just a single part

- Withstands high mechanical loads, shock, and vibration

- Press-fit technology eliminates the soldering process

- Customized board-to-board distance as an option

- Press-fit system: Tcom press

Applications

- LED in building, automation, and automotive technologies

- Drive technology

- Sensors

flexilink b-t-b Features

Features

- Up to 11 Ampere current rating per pin

- 2–90 pins

- 5–25 millimeters in height

- 1–3 rows

- Saves space and reduces costs; replaces spacers

- Connection created using just a single part

- High mechanical load, shock, and vibration

- Press-fit technology eliminates the soldering process

- Customized board-to-board distance as an option

- Press-fit system: Tcom press

Applications

- Machine tools

- Agricultural technology

- Automotive

- Intralogistics

- Lifting and crane technology

- Drive technology

Questions & Answers Regarding flexilink Board-to-Board-Connector

Can you also press the flexilink into a thicker copper base?

Yes, the flexilink can be easily pressed into thick copper circuit boards.

Why is there a minimum purchase volume for the flexilink?

The minimum purchase volumes are due to the high consulting effort involved, the complex machine technology, and the installation of the press.

Testimonials about the flexilink Board-to-Board-Connector

We were able to solve our space problems and launch our new development to the market on time with the help of ept’s flexilink.

We were able to use the flexilink to ensure that there were no contact interruptions even in molded assemblies due to ept’s gas-tight press-fit system.

Flexilink allows us to implement the exact board-to-board distances we need.

With the flexilink, we only need one component instead of two to reliably connect PCBs together.

We achieved the best results with flexilink in our extreme shock and vibration tests: There was not a single contract interruption in the joints between the flexilink pins and the PCB’s through connection!”