PC/104, PC/104-Plus

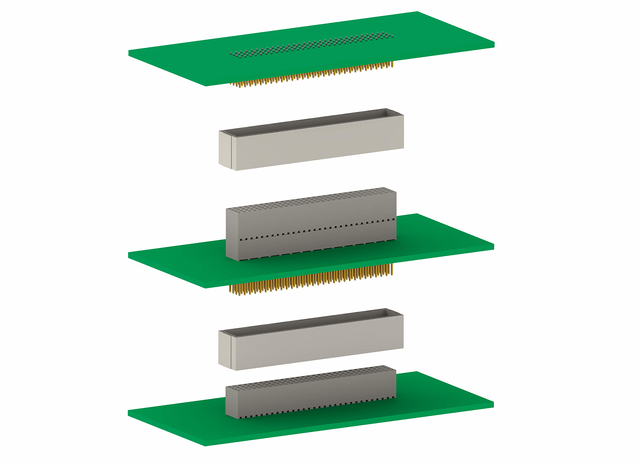

Top Quality with a Proven Form Factor PC/104 and PC/104-Plus are standardizations for computer-on-modules (COM), which are used in industrial computers. In contrast to other form factors, the modules are stacked, so they can be connected to build complex computer systems. Both PC/104 and PC/104-Plus offer complete hardware and software compatibility despite extremely small form factors (96 mm x 90 mm) with a standardized bus system (ISA). This standardization makes it possible for different PC/104 cards to be used together in order to fulfill a specific performance requirement.

Features

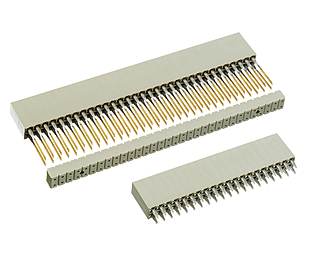

- Tried and proven press-fit technology with Tcom press®

- PC/104-Plus also available with 22-mm pitch

- Shrouds as accessories

- The pin count and/or mechanical load capacity can be modified

- Pitch of 2.54 mm

Applications

- Board-to-board distances of 15.24 mm and 22 mm

PC/104: Overview

Filter

PC/104 Female connectors

PC/104 Female connectors Part No. 962-40202-03

termination length 3.4 mm, 40 contacts, performance level 3

Parallel

Through Hole

PC/104 Female connectors Part No. 962-40206-03

termination length 3.4 mm, 40 contacts, performance level 2

Parallel

Through Hole

PC/104 Female connectors Part No. 962-40322-03

termination length 3.4 mm, 64 contacts, performance level 3

Parallel

Through Hole

PC/104 Female connectors Part No. 962-40326-03

termination length 3.4 mm, 64 contacts, performance level 2

Parallel

Through Hole

PC/104 Female connectors Part No. 962-60202-03

termination length 3.4 mm, 40 contacts, performance level 3

Parallel

Press-fit

PC/104 Female connectors Part No. 962-60202-12

termination length 12.2 mm, 40 contacts, performance level 3

Parallel

Press-fit

PC/104 Female connectors Part No. 962-60206-03

termination length 3.4 mm, 40 contacts, performance level 2

Parallel

Press-fit

PC/104 Female connectors Part No. 962-60206-12

termination length 12.2 mm, 40 contacts, performance level 2

Parallel

Press-fit

PC/104 Female connectors Part No. 962-60322-03

termination length 3.4 mm, 64 contacts, performance level 3

Parallel

Press-fit

PC/104 Female connectors Part No. 962-60322-12

termination length 12.2 mm, 64 contacts, performance level 3

Parallel

Press-fit

PC/104 Female connectors Part No. 962-60326-03

termination length 3.4 mm, 64 contacts, performance level 2

Parallel

Press-fit

PC/104 Female connectors Part No. 962-60326-12

termination length 12.2 mm, 64 contacts, performance level 2

Parallel

Press-fit

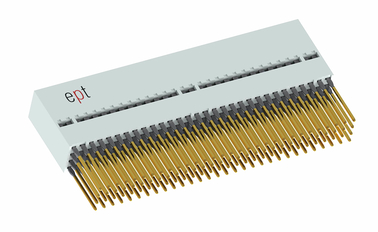

PC/104-Plus Straight pin header

PC/104-Plus Straight pin header Part No. 272-30000-31

termination length 2.8 mm, 60 contacts, performance level 3

Parallel

Press-fit

PC/104-Plus Female connectors

PC/104-Plus Female connectors Part No. 264-40303-02

termination length 2.8 mm, 120 contacts, performance level 3

Parallel

Through Hole

PC/104-Plus Female connectors Part No. 264-60303-02

termination length 2.8 mm, 120 contacts, performance level 3

Parallel

Press-fit

PC/104-Plus Female connectors Part No. 264-60303-12

termination length 12 mm, 120 contacts, performance level 3

Parallel

Press-fit

PC/104-Plus Female connectors 22 mm

PC/104-Plus Female connectors 22 mm Part No. 264-61303-02

termination length 2.8 mm, 120 contacts, performance level 3, for 22 mm board-to-board distance

Parallel

Press-fit

PC/104-Plus Female connectors 22 mm Part No. 264-61303-12

termination length 12 mm, 120 contacts, performance level 3, for 22 mm board-to-board distance

Parallel

Press-fit

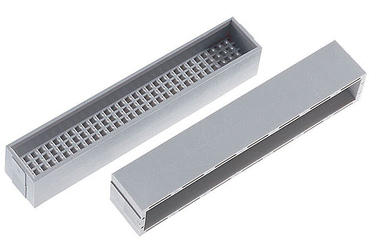

PC/104-Plus Accessories

PC/104-Plus Abstandshalter Part No. 264-16302

120 contacts

PC/104-Plus Shroud Part No. 264-17302

120 contacts

Features

The PC/104 and PC/104-Plus connectors offer the proven press-fit technology Tcom press® from ept. This means it is possible to have board-to-board distances of 15.24 mm and 22 mm. The number of contacts and/or mechanical load capacity can be modified, giving you the opportunity to develop complete custom solutions.

The PC/104 and PC/104-Plus standard:

Constant advances in component performance made it necessary to expand the PC/104 system to include a faster bus system. As a result, a PCI bus was added to the PC/104 system. This addition is referred to in the specification as PC/104-Plus.

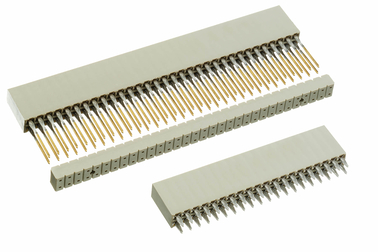

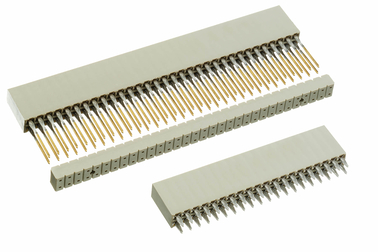

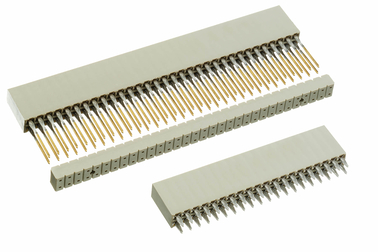

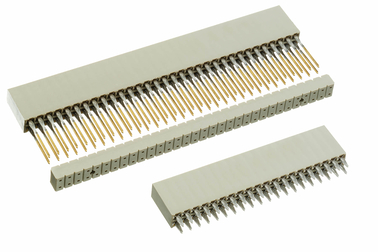

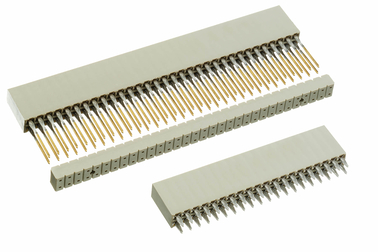

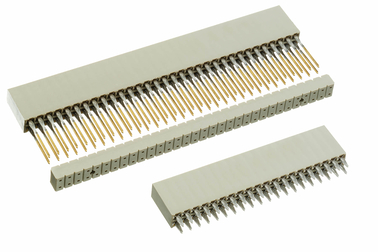

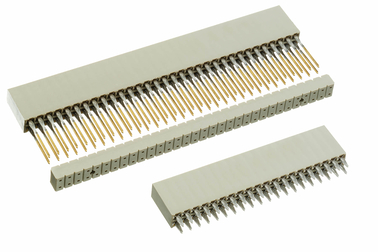

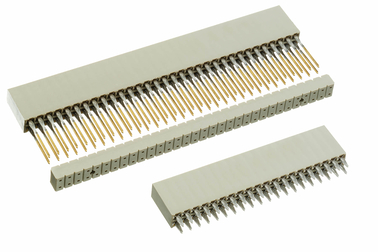

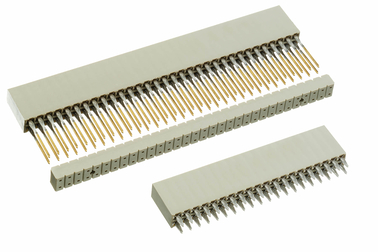

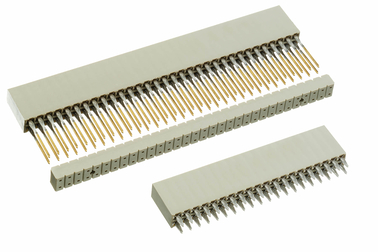

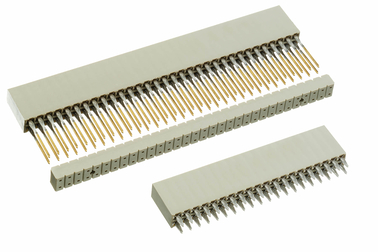

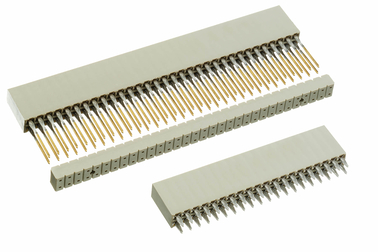

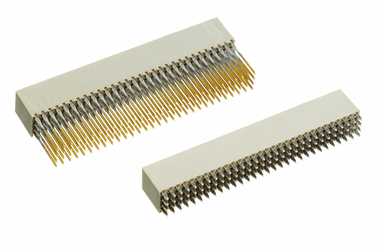

PC/104 and PC/104-Plus connectors

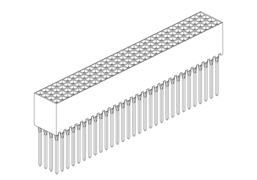

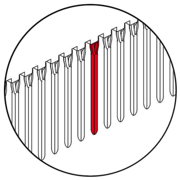

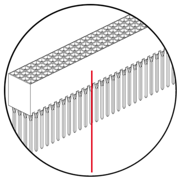

The PC/104 bus consists of two parallel connectors with 40 and 64 pins and a pitch of 2.54 mm, whereas the PC/104-Plus already has 120 pins spaced at a distance of 2.00 mm and arranged in four rows.

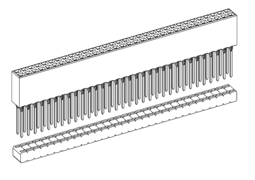

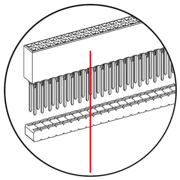

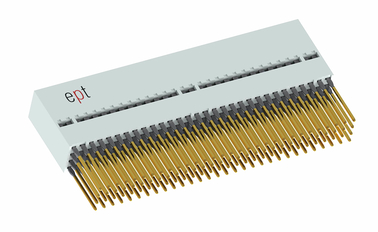

Several boards can be conveniently stacked on top of each other (see illustration) by using connectors with the rear mating zone (long pins) in press-fit technology. The distances specified by the PC/104 consortium are maintained by using spacers and shrouds. This eliminates the additional need for spacer bolts.

PC/104 and PC/104-Plus connectors

The PC/104 bus consists of two parallel connectors with 40 and 64 pins and a pitch of 2.54 mm, whereas the PC/104-Plus already has 120 pins spaced at a distance of 2.00 mm and arranged in four rows.

Several boards can be conveniently stacked on top of each other (see illustration) by using connectors with the rear mating zone (long pins) in press-fit technology. The distances specified by the PC/104 consortium are maintained by using spacers and shrouds. This eliminates the additional need for spacer bolts.

Developer view:

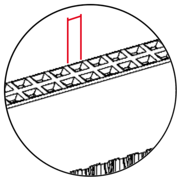

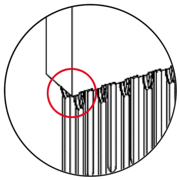

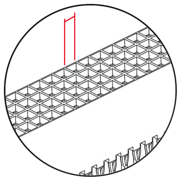

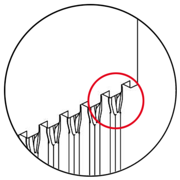

The ept connectors are characterized by the highest stamping quality, which is particularly evident in the clean stamping of the rear mating zones. A high number of mating cycles is guaranteed due to the processing quality and the available performance levels. ept PC/104 and PC/104-Plus connectors are supplied with the Tcom press® press-fit zone, which is well-known and proven in the market and thus able to ensure maximum reliability in all conceivable applications.

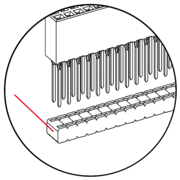

The female connectors are pressed in with a simple flat plate press-fit tool, eliminating the cost of time-consuming hand soldering and any reworking on the rear mating zone (solder bridges, solder splashes). A guiding block is pushed up from below to stabilize the rear mating zone when pressing in the female connectors with interchange post. It also serves as a spacer, so that the distance of 0.6 inches is achieved when the modules are plugged in.

The female connectors are pressed in with a simple flat plate press-fit tool, eliminating the cost of time-consuming hand soldering and any reworking on the rear mating zone (solder bridges, solder splashes). A guiding block is pushed up from below to stabilize the rear mating zone when pressing in the female connectors with interchange post. It also serves as a spacer, so that the distance of 0.6 inches is achieved when the modules are plugged in.

FAQ:

Can you also press the flexilink into a thicker copper base?Why is there a minimum purchase volume for the flexilink?

Can you also press the flexilink into a thicker copper base?

Yes, the flexilink can be easily pressed into thick copper circuit boards.

Why is there a minimum purchase volume for the flexilink?

The minimum purchase volumes are due to the high consulting effort involved, the complex machine technology, and the installation of the press.